Most Used Storage Rack Warehouse Rack Logistics Multi Shelf for Various Pallet.

Overview Product DescriptionProduction Description Pallet racks are called heavy-duty racks. They are the most common am;

Basic Info

| Model NO. | Pallet Rack |

| After-sales Service | Door to Door Service |

| Warranty | 10 Years |

| Usage | Tool Rack, Beverage, Clothing, Tools, Supermarket, Industrial, Warehouse Rack |

| Material | Steel |

| Structure | Rack |

| Type | Pallet Racking |

| Mobility | Fixed |

| Height | Maximum 12000mm |

| Weight | 1000-4000kg |

| Closed | Open |

| Development | Conventional |

| Serviceability | Common Use |

| Use | Warehouse Rack, Shelf |

| Weight Capacity | 1000-4000kg Per Tier |

| Color | Optional |

| Surface Treatmen | Electrostatic Spraying |

| Drawing Design | Free |

| Installation | Installation Teams Availiable |

| Accessories | Standard |

| Certification | CE, ISO9001, 14001 |

| Features | Versatility, Stability and Durability |

| Pitch | 75mm |

| Width | 1350-3900 mm |

| Thickness | 1.5mm-3.0 mm |

| Transport Package | Plastic Wrap |

| Trademark | JISE |

| HS Code | 730890 |

| Production Capacity | 6000tons/Year |

Product Description

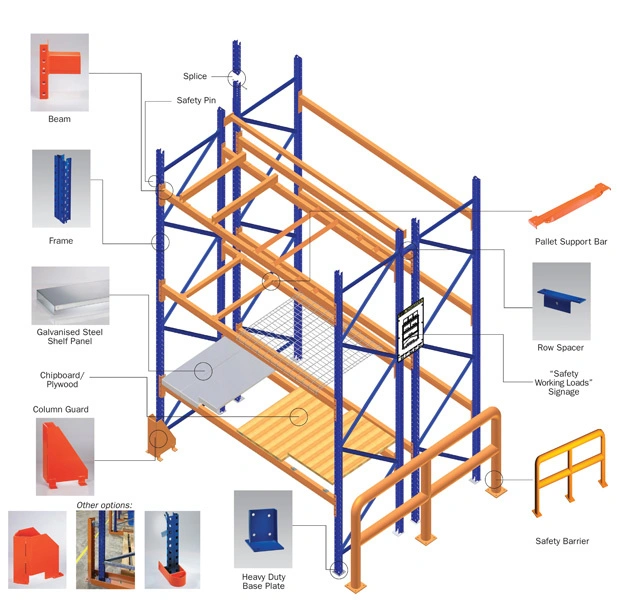

Pallet racks are called heavy-duty racks. They are the most common among all types of storage racks and are the most widely used. The plug-in combined structure is mainly assembled by columns, beams, horizontal bracings, diagonal bracings, and self-locking bolts.It is convenient and flexible to install and disassemble. The shelf height can be adjusted every 75mm. Use forklifts to access operations, which can be equipped with ordinary forklifts, counterbalanced forklifts, forward-moving forklifts, and other handling equipment.

Also suitable for many varieties and small quantities of goods, and it is suitable for few varieties and large quantities of goods. This kind of shelf is most used in high warehouses and ultra-high warehouse Detailed introduction

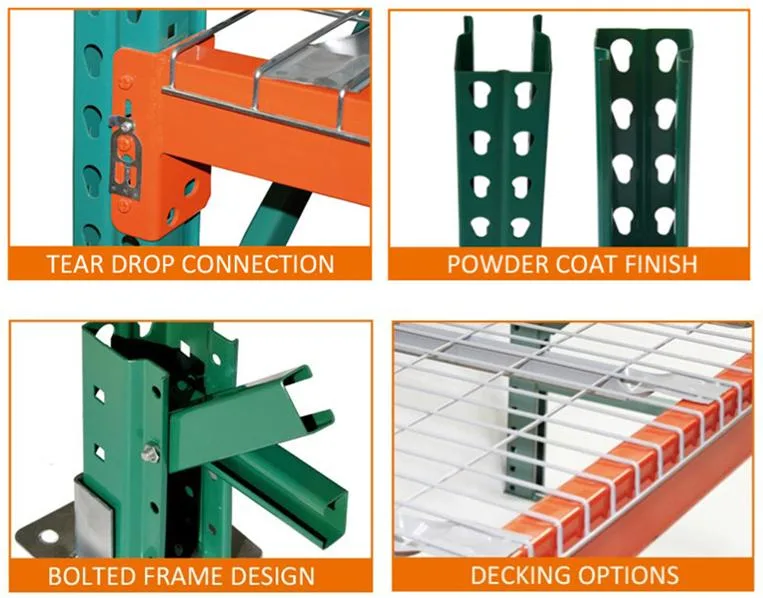

American Pallet Racks from JISE are the most cost-effective system for storing pallets and bulky goods, maximizing the use of warehouse space. American Teardrop racks can be used for a variety of storage needs, including standard storage for palletized goods, narrow aisle storage, push-in storage, gravity storage, columnar storage, cable storage, retail shelving, shelving lofts, and picking modules Wait. The JISE racking American Teardrop pallet racking system is designed and manufactured in full compliance with the requirements of RMI (Rack Manufacturers Association of America).The column hole distance of the rack is 2"50.8mm, and the user can adjust the height arbitrarily according to their own needs. The 3-rivet or 4-rivet beam joint of the JISE American Teardrop pallet racking system adopts the design concept of enhanced lateral bending moment resistance. The joint design improves the joint's ability to withstand vertical pressure and bending

Pallet Rack Features & Advantages:

- Access a large range of Stock Keeping Units (SKUs)

- First In First Out (FIFO) inventory management.

- Cheapest type of racking (Per square meter)

- Multiple access (more than one truck in the same aisle)

- No special truck requirements

- Lower Forklift or Pallet Handling costs; as standard forklifts are cheaper than specialized equipment.

- Optimizing Warehouse Space.

- Increasing Bulk Storage Capacity.

- Cost saving, no need to install laminates

- Large moment of inertia, strong loading capacity, strong impact resistance, lightweight.

- The hole shape of the column is water drop type, which is more beautiful and more in line with American aesthetics.

- The interlocking assembly structure of the beams can achieve heavier load-carrying capacity and look more solid and aesthetically pleasing.

- Available in different sizes.

Supply Ability: 10 Carton/Cartons per Day

Packaging & DeliveryPackaging Details: 1. One type of part in one pallet. 2. Suitable quantity to an export pallet. 3. No other packing accessories in regular. 4. Customer-required packing is available. Port: Nanjing, Shanghai, or others.Lead Time: About 20-40 days after order details and production are confirmed.Certifications

We are Jiangsu JISE Intelligent Storage Equipment Co.ltd. Which are a high-tech enterprise specializing in the planning, design, manufacturing, installation, debugging, maintenance, and consulting services of various storage equipment and storage systems.

JISE has been focusing on the warehousing industry for many years and has a group of high-quality design and R&D teams. With professional manufacturing experience, leading production equipment, excellent product quality, and honest business philosophy, we will provide every customer with high-quality products. With a full range of services, it enjoys a high reputation among partners and is the preferred storage equipmentWe are located in Dongtai City, Jiangsu Province. It covers an area of 35,000 square meters. It has various advanced automatic production lines for storage equipment, domestic first-class automatic electrostatic powder coating lines, and an average annual production capacity of 40,000 tons.

JISE products are widely used in e-commerce, machinery, electronics, automobiles, pharmaceuticals, electric power, clothing, and other industries, with product sales covering the world.

JISE products have been spread all over the country, and we have undertaken more than 100 storage rack projects. Since its establishment, we have signed 20 million sales of 26 million sales of JD, Vipshop, and 16 million sales of Geek+.Our Advantages

Advantages of laser cutting services:

- Laser cutting machines are highly efficient and design replicas are exact copies of each other.

- It requires and consumes less amount of energy to cut sheets of all types of materials.

- In comparison with traditional scissors, laser cutting machines take less time to cut large sheets and the outcome is extremely accurate.

- The entire process is monitored by computer programs which reduce the amount of work and workload.

- Much human intervention is not required except for maintenance and observation. No danger of accidents or injuries

- Very flexible, can be used to cut almost all types of materials.

- Precise cuts can be obtained within a short time.

You may also like

Send inquiry

Send now