The Latest Warehouse Rack Multi Storage Rack Supported Mezzanince for Plastic Pallet.

Basic Info

| Model NO. | rack supported mezzanince |

| Mobility | Fixed |

| Height | 5-15m |

| Weight | 200-3000kg |

| Closed | Open |

| Development | Conventional |

| Serviceability | Common Use |

| Use | Warehouse Rack, Shelf |

| Color | Optional |

| Surface Treatmen | Powder Coated |

| Drawing Design | Free |

| Installation | Installation Teams Availiable |

| Accessories | Standard |

| Certification | CE, ISO9001, 14001 |

| Features | Versatility, Stability and Durability |

| Pitch | 50mm |

| Transport Package | Plastic Wrap |

| Specification | 60*50mm |

| Trademark | JISE |

| Origin | China |

| HS Code | 730890 |

| Production Capacity | 5000PC/Month |

Product Description

Steel mezzanines are a common type of mezzanine construction for warehouse storage, equipment platforms, and other industrial spaces. Steel construction offers high strength for a durable and safe structure.

Steel mezzanines and equipment platforms can be designed to be free standing structures with bolt-together construction for easy to assembly inside an existing building. This makes steel the best choice for adding a mezzanine floor to an existing space.

A rack mezzanine is a storage mezzanine or warehouse mezzanine floor designed using the storage rack system as the primary structural support for the mezzanine. This type of support structure can help save money and space since the supports are used for both the rack and the mezzanine systems.

Concrete is often used for mezzanine floor decking. It is the most durable type of mezzanine floor decking system with high point load and low noise transmission.

What is a mezzanine level used for?A mezzanine is an intermediate level or levels between the floor and ceiling of any story in accordance with Section 505 of the International Building Code. Mezzanine meaning derives from the Italian word mezza which means "half" or "middle."

A mezzanine level is an intermediate floor between levels of a building that is used for increasing the floor area of the building without adding on to the building itself. It can be used for countless applications like storage, work operations, equipment access, inventory rack access, and conveyor access.Mezzanines are common in industrial settings in buildings with high ceilings like distribution centers, warehouses, and production floors. No matter the use of the mezzanine, it should meet certain building code requirements, and the mezzanine access stairs must meet the IBC mezzanines stair requirements. Future development prospect

- Versatility and flexibility to meet any storage needs;

- The most commonly use for palletised goods in all storage systems;

- Low capital cost;

- Easy to install and simple to adjust;

- Compatible with most types of handling equipment;

- Less storage density compared to other pallet racking systems;

- Infinitely adjustable and offering a wide range of options and components;

- Maximizes space use in any warehouse configuration while retaining optimum product accessibility;

- quality garantee 3 years;

- More than 300 workers enable us to garantee the delivery time, normal orders witin 20days;

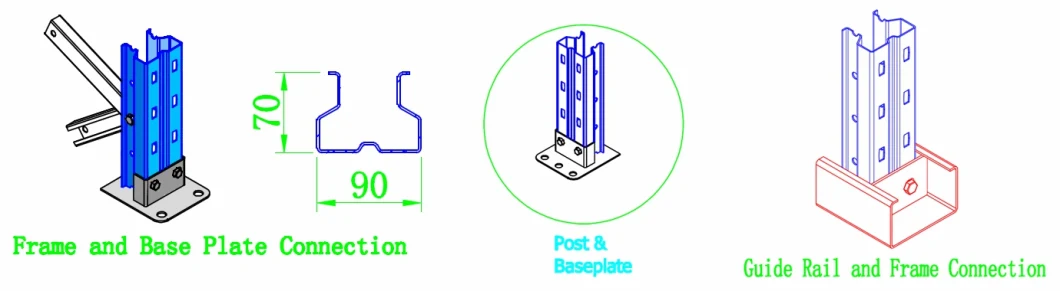

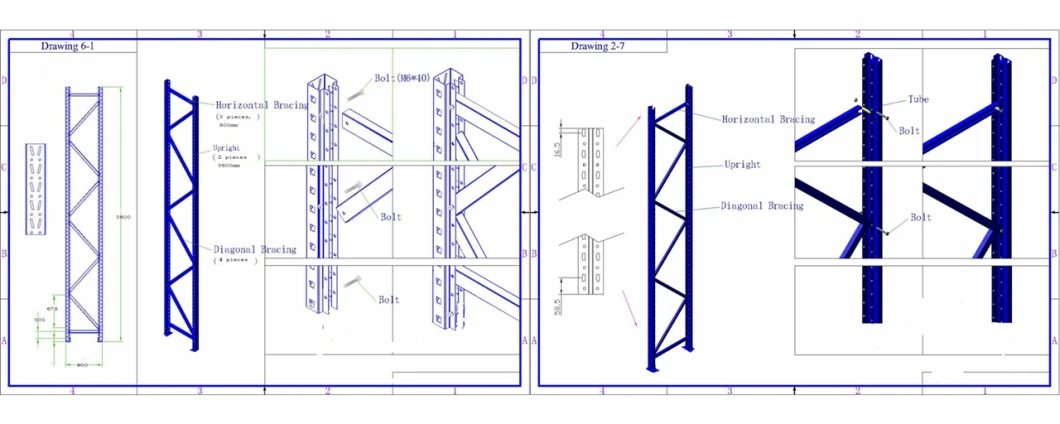

1. Measure and plan the space: Measure the area where you plan to install the mezzanine and plan the layout. Determine the height of the mezzanine, the dimensions of the platform, and the placement of the support columns.

2. Prepare the site: Clear the area where you will be installing the mezzanine and ensure that the ground is level and stable. Mark the locations for the support columns and ensure that they are level and plumb.

3. Install the support columns: Install the support columns using anchor bolts or other appropriate fasteners. Ensure that they are securely anchored to the floor and ceiling.

4. Install the beams: Install the beams on top of the support columns, ensuring that they are level and properly spaced. Secure the beams to the columns using appropriate hardware.

5. Install the decking: Install the decking on top of the beams, ensuring that it is level and properly secured. Use appropriate fasteners to attach the decking to the beams.

6. Install safety features: Install safety features such as guardrails and handrails to ensure that the mezzanine is safe and secure.

7. Inspect and test: Inspect the completed mezzanine and test its load capacity to ensure that it is safe and secure.

Supply Ability

Supply Ability: 10 Carton/Cartons per Day

Packaging & DeliveryPackaging Details: 1. One type of part in one pallet. 2. Suitable quantity to an export pallet. 3. No other packing accessories in regular. 4. Customer-required packing is available. Port: Nanjing, Shanghai, or others.Lead Time: About 20-40 days after order details and production are confirmed.Certifications

Factory

Advantages of laser cutting services:

- Laser cutting machines are highly efficient and design replicas are exact copies of each other.

- It requires and consumes less amount of energy to cut sheets of all types of materials.

- In comparison with traditional scissors, laser cutting machines take less time to cut large sheets and the outcome is extremely accurate.

- The entire process is monitored by computer programs which reduce the amount of work and workload.

- Much human intervention is not required except for maintenance and observation. No danger of accidents or injuries

- Very flexible, can be used to cut almost all types of materials.

- Precise cuts can be obtained within a short time.

We are Jiangsu JISE Intelligent Storage Equipment Co.ltd. Which are a high-tech enterprise specializing in the planning, design, manufacturing, installation, debugging, maintenance, and consulting services of various storage equipment and storage systems.

JISE has been focusing on the warehousing industry for many years and has a group of high-quality design and R&D teams. With professional manufacturing experience, leading production equipment, excellent product quality, and honest business philosophy, we will provide every customer with high-quality products. With a full range of services, it enjoys a high reputation among partners and is the preferred storage equipmentWe are located in Dongtai City, Jiangsu Province. It covers an area of 35,000 square meters. It has various advanced automatic production lines for storage equipment, domestic first-class automatic electrostatic powder coating lines, and an average annual production capacity of 40,000 tons.

JISE products are widely used in e-commerce, machinery, electronics, automobiles, pharmaceuticals, electric power, clothing, and other industries, with product sales covering the world.

JISE products have been spread all over the country, and we have undertaken more than 100 storage rack projects. Since its establishment, we have signed 20 million sales of 26 million sales of JD, Vipshop, and 16 million sales of Geek+.