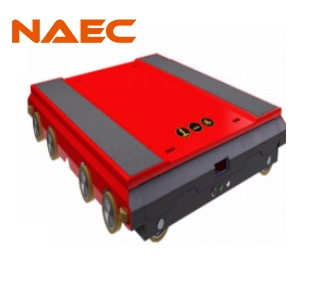

Automatic Racking Four Way Shuttle 4-Direction Robot for Racking Automated Storage System

Basic Info

| Model NO. | Customized |

| Place of Origin | Jiangsu, China (Mainland) |

| Color | Red,Blue,Black,etc. |

| After-Sales Service Provided | 1 Year |

| Transport Package | Container |

| Trademark | NAEC |

| Origin | China |

| Production Capacity | 500000 Sets/Year |

Product Description

Item | Specification |

Loading capacity | 1000kg |

Running speed | 0~120m/min |

Traveling mode | Four-direction |

Rated duration time | 8h |

Application temperature | -10~45ºC |

Noise | <75dB |

Shuttle racking adopts shuttle cart as the main access equipment. The storage capacity of the system can reach 80%. The wireless remote controller of shuttle car can ensure the personal safety, and add fun to warehousing operation. The guide rail produced by special forming machine ensures the smooth operation of the system.

Our Advantages

1 Achieve the highest density of storage, significantly reduce the cost of warehouse construction

2 Goods can be freely chosen First in first out or first in and then out

3 Realize that the drive-in racking does not need to drive in, and the efficiency of entering and discharging goods is high.

4 Seismic safety performance is much higher than drive in racking.

1, What is MOQ limitation for rack system?++ NO. But large purchase will bring competitive prices, 20FT container ( 10T~13T) is highly recommended, so that production can be better handled.

2, What is the lead time++ As per 20FT container loading, manufacture time is about 10-15 days; Regarding some customized items 20-25 days will be covered.

3, What is payments methods you can accept?++ T/T and L/C are welcomed.

4, How about your sample delivery?++ Short section of uprights and beams can be provided free of charge. But the freight will be collected upon your duty.

5, What is warranty for your rack system?++ All rack items will be warrantied against manufacture's defects.++ To avoid any shortage or missing components, we will provide 1%~2% spare parts besides basic ones.

Our company view Nanjing Auto Electric (NAEC) was established in 2001, taking promoting "Lean Fabrication to Global Energy Engineering Industry" as its mission, NAEC's core business is to provide Lean-fabrication One-stop Solution to energy engineering contractors and fabricators. With advanced innovation ability and continuous integration of new technology & processes, NAEC's solution ensure its users high quality and efficient fabrication, and make itself become worldwide clients' most preferred partner. Our Strategic Clients are EPC companies, Contractors or Fabricators in Onshore Oil & Gas Exploration, Transportation, Storage, Refinery & Chemical EPC companies, Contractors, Fabricators or Equipment Manufacturers in Offshore Oil & Gas Exploration, Treatment, Transportation & Storage EPC companies, Contractors or Fabricators in Nuclear Power, Wind Power, or Thermal Power Various Energy Engineering Equipment Manufacturers We provide Lean-fabrication One-stop Solution for Energy Engineering EPC Companies/ Contractors/ Fabricators, Based on Following Systems: NAEC Lean-fabrication Mode NAEC Lean-fabrication Management System NAEC Lean-fabrication Production System NAEC Lean-fabrication One-stop Solution can help engineering fabrication operators to solve project problems. It can organize fabrication production and ensure the final delivery in good quality and on time.

Pipe Spool Fabrication Machines

| 1 | Pipe Cutting& Beveling All-in-one Machine >Suitable for pipes not larger than 8",max.thickness:20mm >Cutting efficiency:100times/8hrs >PLC control with automatic measuring to guarantee the same processing cycle >Widely used for small bore C.S/S.S production lines | |

| 2 | High Speed Band-saw Cutting Machine >Three models available(16"type,24"type",48"type) >PLC system control;self-measuring function with precision:±0.5mm >Using hydraulic self-centering chuck >It only takes 6 minutes to cut a 24" pipe of 25mm thickness >Widely used for C.S/S.S production lines. | |

| 3 | High Speed CNC Pipe End Beveling Machine >Automatic self-centering chuck >Single V,double V,U type bevel >Can be matched with pipe end turning devic >High speed beveling:for example,it only takes 2.5minutes to get a 37.5 degree bevel for a S.S pipe end(diameter :610mm,thickness:25mm) >Several models available:16",24",32",48" | |

| 4 | Two / Multi- Axis CNC Flame/Plasma Cutting Machine>High efficient pipe cutting with automatic self-measuring function, pipe end beveling, intersection line profiling for both main and branch pipe. >Five/multi-axis cutting machine can profile more complicated outlines with various bevel type >Standard machine suitable for pipes nor larger than 24'' | |

| 5 | Multi-function Pipe Fitting-up Station >Suitable for flange,elbow,tee,reducer to pipe and special T-joint fitting-up. >Light-duty type(manual) and heavy-duty type(motorized) are available. >Different types available, 8" type, 24" type, 32" type, 48" type, 60" type | |

| 6 | Automatic Pipe Welding Station >With two welding heads >TIG/MIG/SAW are optional >PLC system control & WPS programmed >Max. efficiency fo reach welding head can be 400D.I/8hrs even use TIG/MIG technology. >Different types available, 8" type, 24" type, 32" type, 48" type, 60" type | |

| 7 | Conveyor Handling System >used for pipe convenient transporation during in pipe spool fabrication. >Its speed is adjustable between 2M to 20M/min. |

Tank Construction Machines

| 1 | Girth Seam Welding Machine >Applicable to both bottom-to-top and top-to-bottom tank erection >Adopting Sub Arc Welding technology >Standard machine suitable for shell plate width: 1.3M-2.8M >Max. Efficiency of AGW could be 30 times as manual welding | |

| 2 | Vertical Seam Welding Machine >Suitable for tank plate wall thickness is from 10mm to 50mm >Motor frequency inverter drive system >Weatherproof control box with digital display for welding speed >Travel speed: 0~2200mm/min >Beveled gear drive reducer, good locking ability in both directions | |

| 3 | Butt/Corner Seam Welding Machine >Applicable to butt seam welding of bottom plates >With magnetic idler system >More than 99% Qualified first X-ray test. >Suitable for both Top-to-Bottom and Bottom-to-Top Tank Construction Method |