Jise Automated Display and Storage Rack Easy Installation with a Unique Mounting System Logistics Gravity Flow Racking.

Basic Info

| Model NO. | Gravity flow racking |

| Mobility | Fixed |

| Height | Maximum 12000mm |

| Weight | 1000-4000kg |

| Closed | Open |

| Development | Conventional |

| Serviceability | Common Use |

| Use | Warehouse Rack, Shelf |

| Weight Capacity | 1000-4000kg Per Tier |

| Color | Optional |

| Surface Treatmen | Powder Coated |

| Drawing Design | Free |

| Installation | Installation Teams Availiable |

| Accessories | Standard |

| Certification | CE, ISO9001, 14001 |

| Features | Versatility, Stability and Durability |

| Pitch | 75mm |

| Width | 1350-3900 mm |

| Thickness | 1.5mm-3.0 Km |

| Trademark | JISE |

| HS Code | 730890 |

| Production Capacity | 6000tons/Year |

Product Description

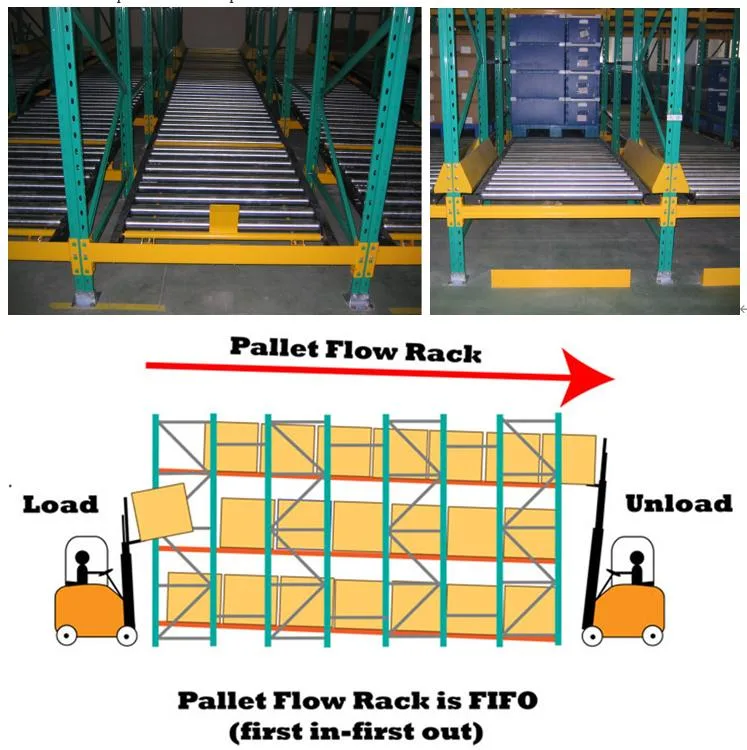

How Does Gravity Flow Racking Work?

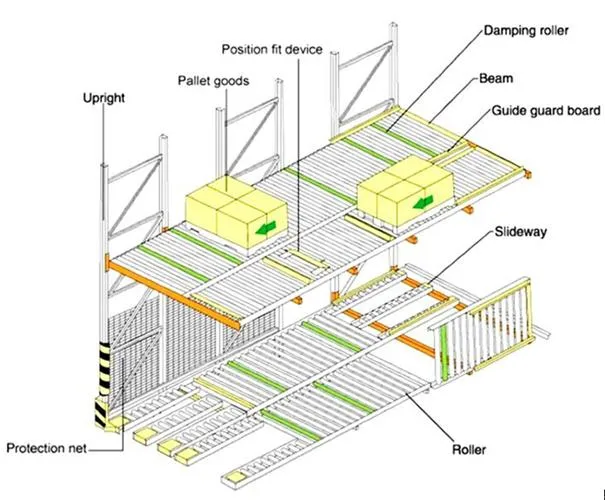

Gravity flow racks act as non-powered, downward-sloped storage conveyors, which allow for all subsequent pallets or cartons to move to the forefront, once the preceding item has been removed, otherwise known as first in first out (FIFO) racking.

Items are loaded into the high end of the rack, one by one. Within a confined lane, the product then travels forward over a deck of wheels or rollers, down the shelf, filling the structure from front to back end.

In utilizing gravitational forces, pallets and cartons naturally find their path, filing in an orderly fashion, while consistently refilling the forward-most position for easy retrieval.

Why Choose Gravity Flow?

Gravity flow racking uses space efficiently providing high-density storage. The FIFO aspect of gravity flow racking and the natural flow of products makes it easier for workers to access the stock they seek, either by forklift or manual picking for smaller items.

Gravity Flow Carton Flow Racking

Gravity flow carton flow racks are the essential solution for companies looking to increase stored product accessibility. In each storage bay, many levels of carton flow racking can exist - each individually customizable.

Cartons are sent down the shelf's slope categorically, each lane containing a specific product, easily identified by its fore-facing label. By organizing cartons in this fashion, with the foremost carton consistently revealing exactly what that lane contains, pickers can select specific cartons with greater efficiency.

This gravity flow system allows for full carton and single item picks, perfect for applications with numerous SKUs.

It's important to remember that the type of gravity flow racking applied to both carton and pallet racking depends on the size and weight of the case, as well as the operating environment.

Detailed Photos

Supply Ability: 10 Carton/Cartons per Day

Packaging & DeliveryPackaging Details: 1. One type of part in one pallet. 2. Suitable quantity to an export pallet. 3. No other packing accessories in regular. 4. Customer-required packing is available. Port: Nanjing, Shanghai, or others.Lead Time: About 20-40 days after order details and production are confirmed.CertificationsFactoryCompany Information

We are Jiangsu JISE Intelligent Storage Equipment Co.ltd. Which are a high-tech enterprise specializing in the planning, design, manufacturing, installation, debugging, maintenance, and consulting services of various storage equipment and storage systems.

JISE has been focusing on the warehousing industry for many years and has a group of high-quality design and R&D teams. With professional manufacturing experience, leading production equipment, excellent product quality, and honest business philosophy, we will provide every customer with high-quality products. With a full range of services, it enjoys a high reputation among partners and is the preferred storage equipmentWe are located in Dongtai City, Jiangsu Province. It covers an area of 35,000 square meters. It has various advanced automatic production lines for storage equipment, domestic first-class automatic electrostatic powder coating lines, and an average annual production capacity of 40,000 tons.

JISE products are widely used in e-commerce, machinery, electronics, automobiles, pharmaceuticals, electric power, clothing and other industries, with product sales covering the world.

JISE products have been spread all over the country, and we have undertaken more than 100 storage rack projects. Since its establishment, we have signed 20 million sales of 26 million sales of JD, Vipshop, and 16 million sales of Geek+.Our Advantages

Advantages of laser cutting services:

- Laser cutting machines are highly efficient and design replicas are exact copies of each other.

- It requires and consumes less amount of energy to cut sheets of all types of materials.

- In comparison with traditional scissors, laser cutting machines take less time to cut large sheets and the outcome is extremely accurate.

- The entire process is monitored by computer programs which reduce the amount of work and workload.

- Much human intervention is not required except for maintenance and observation. No danger of accidents or injuries

- Very flexible, can be used to cut almost all types of materials.

- Precise cuts can be obtained within a short time.